Thermoplastic elastomer TPV

1、 TPV Introduction

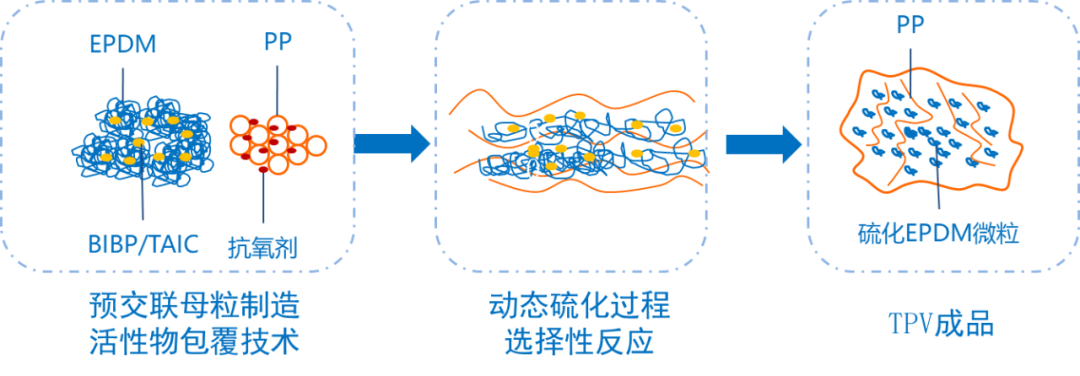

Thermoplastic dynamic vulcanized rubber (TPV) is a kind of thermoplastic elastomer (TPE). It is a new polymer material developed in the 1950s. It is a new polymer material with both high elasticity of rubber and plastic thermoplasticity. It shows rubber elasticity at room temperature and can be plasticized like plastic at high temperature. TPV is a blend thermoplastic elastomer, which is a thermoplastic vulcanized rubber blended with thermoplastic (PP, PE, PS, PA, etc.) as the continuous phase and vulcanized rubber (EPDM, NBR, ACM, SEBS, etc.) as the dispersed phase. It is a thermoplastic elastomer with a high content of dynamically crosslinked rubber particles as the dispersion phase and a small amount of thermoplastic resin as the continuous phase prepared by dynamic vulcanization reactive blending technology.

Characteristics of TPV

1) Standard plastic processing equipment and process can be used for molding, without vulcanization;

2) No reinforcing agent is added, and the strength characteristics are good;

3) The hardness is easy to adjust, and the formula can be adjusted;

4) Thermoplastic material, recyclable;

5) It has cost advantage.

2、 Technical situation

Production technology.

1) EPDM has high crosslinking degree, good elasticity and good compression set performance

2) Low degradation degree of PP, good mechanical properties of the product

3、 Summary

The performance of TPV is very close to that of traditional thermosetting vulcanized rubber, and it can replace thermosetting vulcanized rubber in many application fields, fundamentally solving the problem of recycling and reuse of traditional cross-linked rubber. In addition, TPV has special properties such as high temperature resistance. Therefore, TPV has developed rapidly in the world in recent years.