Antibacterial masterbatch for spinning

In recent years, the body unsuitable malignant events caused by microorganisms are on the rise. Daily necessities such as toothbrushes, clothing, toys, cars and other products are easy to breed bacteria. Therefore, more and more antibacterial products enter people's lives and are recognized. People put forward new requirements of "antibacterial, bacteriostatic and mildewproof" for frequent contact with plastic products in life.

01 Why should it be made into special antibacterial masterbatch?

1. Make the antibacterial agent have better dispersibility in subsequent processing

The antibacterial agent is generally in powder form, with small particle size, high surface energy and easy agglomeration; During the production process, the antibacterial masterbatch is mixed to improve the dispersion and distribution of the antibacterial agent, which can be better dispersed in the product after subsequent heating and melting. In addition, the special antibacterial masterbatch is the same as the subsequent processing materials, with good matching and compatibility.

2. Stability of preservation antibacterial effect

When antibacterial agents are used directly, problems such as water absorption and oxidation are easy to occur during storage, transportation and use, resulting in the decline of antibacterial effect. After the masterbatch is made, the resin carrier is isolated from air and water, which is conducive to the stability of product quality.

3. Ensure the accuracy of the added amount

The antibacterial masterbatch is close to the resin particles, and the measurement is convenient and accurate. It will not adhere to the mixing equipment and will be mixed evenly with the resin. Therefore, it can ensure the stability of the added amount and thus ensure the quality.

4. Keep the environment clean

The antibacterial agent is generally in powder form, which is easy to fly when added and mixed, causing adverse effects on the workshop environment and human health.

02 Polyester spinning and current difficulties

Antibacterial polyester spinning products are widely used in clothing, cosmetics, kitchen and bathroom cleaning and other fields. In addition to the basic mechanical requirements such as flexibility, hardness and resilience, antibacterial polyester fiber also needs to achieve the expected antibacterial effect. After the antibacterial property of polyester fiber is given, there are some problems, such as difficult to disperse the antibacterial agent evenly, poor antibacterial effect, easy to break the silk during spinning, and unstable wire diameter.

03 Research of Zhantong

In combination with the current difficulties in the polyester spinning industry, Zhantong has developed a special antibacterial master batch for non-silver polyester through strict screening of antibacterial agents and continuous improvement of the process. The masterbatch has the characteristics of small addition, good dispersion effect, durable and efficient antibacterial, and stable spinning and forming.

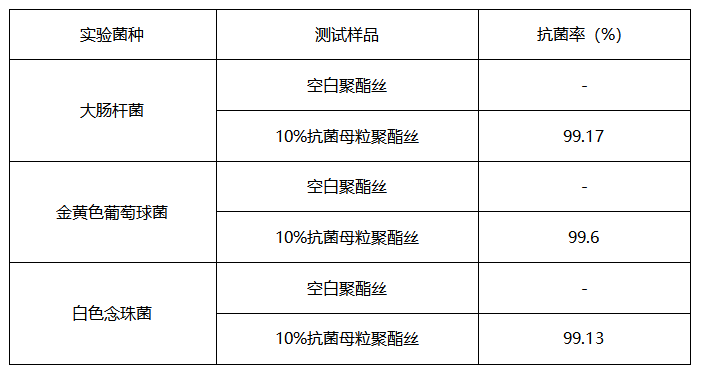

Antibacterial effect

Antibacterial and bacteriostatic: It can coagulate and denature the protein by losing the function of cell membrane. It has the characteristics of rapid sterilization and broad antibacterial spectrum. The antibacterial effect is shown in the table below:

Table 1 Antibacterial Test of Polyester Filament