Toughening method of nylon

Nylon is one of the earliest used engineering plastics and the most widely used engineering plastics at home and abroad. Its excellent properties, such as toughness, wear resistance, impact resistance, fatigue resistance, corrosion resistance, oil resistance and so on, especially its excellent wear resistance and self-lubricating performance, low friction coefficient, make it widely used in many fields.

In the past 40 years, PA has been growing steadily and rapidly in the fierce competition of other engineering plastics, and its demand has been ranked first among the five engineering plastics. Only China's PA demand has increased rapidly from 3.218 million tons in 2015 to 4.962 million tons in 2019.

In the current application field, the toughness of PA has higher requirements, so the toughening modification of PA has important theoretical and practical significance. In recent 20 years, a lot of researches on Toughening of PA have been carried out by scholars at home and abroad

#1、Blending of different PA varieties

Compared with other engineering plastics, PA is a kind of high toughness material, especially some long carbon chain PA, such as PA11, PA12, pa1212, etc. their toughness is very good. But in order to get better cost-effective materials, the general method is to blend different PA varieties to produce high performance alloys.

#2、PA/Polyolefin

PA and non-polar polyolefin are not compatible with each other, but by using the latest compatibility technology and blending technology, practical PA / polyolefin alloys with high performance, such as PA / PE and PA / PP, can be prepared.

In addition, Japanese scholars have studied the situation when LDPE is blended with PA6. The results show that the dry state and low temperature impact strength of ldpe/pa6 blends are also doubled, and the indexes are increased by 7-8 times when the LDPE content reaches 40%.

#3、PA/Polyolefin elastomer

This alloy can also increase the impact strength of PA in dry state at low temperature and reduce the moisture absorption. In particular, the blend of PA and functionalized polyolefin elastomer is also called super tough PA.

#4、PA/High performance engineering plastics

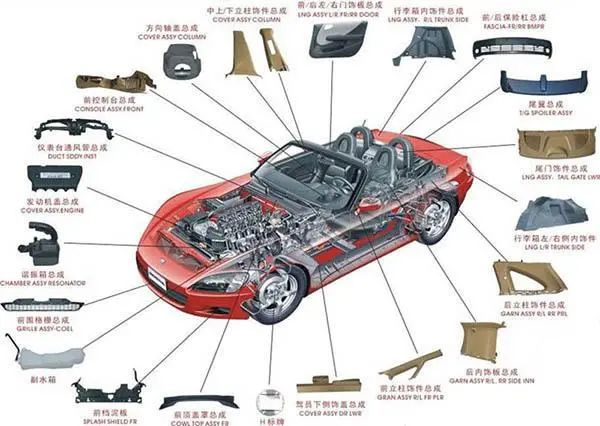

This kind of copolymers can improve the heat resistance and comprehensive properties of PA, so they are widely used in automotive interior and exterior decoration.

#5、PA/Organic low molecular weight

Domestic R & D team has studied the toughening effect of new aromatic sulfonamides on pa1212. The results show that the brittle ductile transition of pa1212 can be achieved with 10% toluenesulfonamide and polyacrylamide. After toughening, the impact strength of pa1212 increases greatly, reaching 739.92j/m, and the elongation at break also increases significantly.

#6、PA/Inorganic matter

The size of inorganic rigid particle filler has a great influence on the modification effect, which is generally divided into conventional filler (> 5 μ m) 1 nm-5 μ m) And nano filler (< 0.1 1 μ m) There are also special fillers such as fiber and ball.

Changchun Institute of Applied Chemistry, Chinese Academy of Sciences has developed inorganic rigid particle toughening agent with rubidium oxide as filler to strengthen PA6. The results show that the impact strength and toughness of PA6 are also significantly improved.

The above six aspects are the current mainstream toughening methods for PA materials. Among them, polyolefin and polyolefin elastomer can improve the impact properties of PA Blends greatly, and the corresponding tensile strength and bending strength will also decrease, and the compatibility is poor; Although the toughness and rigidity of PA and high performance engineering plastics can be improved at the same time, their cost performance is low.