Four flame retardant technologies--Nanotechnology

The flame retardancy of polymer materials is mainly achieved by preventing or slowing down the combustible elements in the matrix. Now there are mainly two ways to express this purpose: adding flame retardant and using flame retardant technology. At present, the overall development trend of flame retardant is to combine flame retardant with flame retardant technology, and make flame retardant more efficient, high performance and low pollution by changing the form of flame retardant and changing the wrapping way of flame retardant.

In 1976, the Japanese patent first reported that nanocomposites have flame retardant properties. However, the research on the flame retardancy of nanocomposites did not really start until recently, after many foreign scholars carried out the research on the thermal stability of nanocomposites.

It is found that when the content of layered silicate (clay) in layered silica nanocomposites is only less than 5%, it has good thermal stability, and its HRR (heat release rate) peak is reduced by more than 50% compared with that when it is not used, and it does not damage other properties of the materials. This shows that the polymer nanocomposites have good thermal properties and can be used in flame retardant technology.

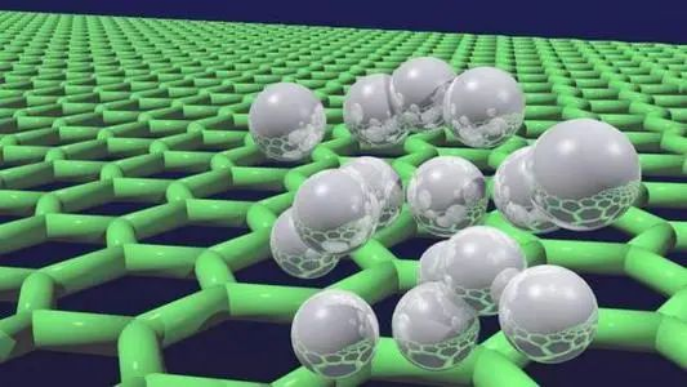

At present, the mainstream method is to use nano inorganic flame retardant. The flame retardant is mainly composed of layered silicate, graphite, layered double hydroxyl hydroxide, carbon nanotubes and other materials, such as nano epoxy resin, polystyrene, polypropylene and other composites. The results show that the tensile strength of nylon 6 / montmorillonite (4.2%) nanocomposites is 50% higher than that of pure nylon 6, the glass transition temperature is about 90 ℃ higher, and the heat release efficiency is much lower.

Polymer / layered inorganic nanocomposites have been widely used in automobile engine parts manufacturing abroad, and will be applied to aircraft interior materials, fuel bunker, electronic and electrical components and tire manufacturing in the future.

Its advantage is that only a small amount of layered silicate and other materials need to be added to maintain the high thermal stability and high safety of the whole material, so as to provide good flame retardant effect. However, with the improvement of flame retardancy, the cost is that the smoke suppression effect may be reduced, and the environmental friendliness of nano flame retardants is worthy of further study.