Four flame retardant technologies--Microcapsules

The overall development trend of flame retardant is the combination of flame retardant and flame retardant technology, through changing the form of flame retardant, transforming the wrapping way of flame retardant and so on, to make flame retardant become more efficient, high performance and low pollution. Microencapsulation, also known as microencapsulation granulation, is a kind of micro container or package with wall shell of polymerization degree.

As the name suggests, microencapsulation is to encapsulate flame retardant in micro containers ranging from several microns to hundreds of microns, so as to protect and control the release. At present, microencapsulation is also a hot new technology of flame retardant.

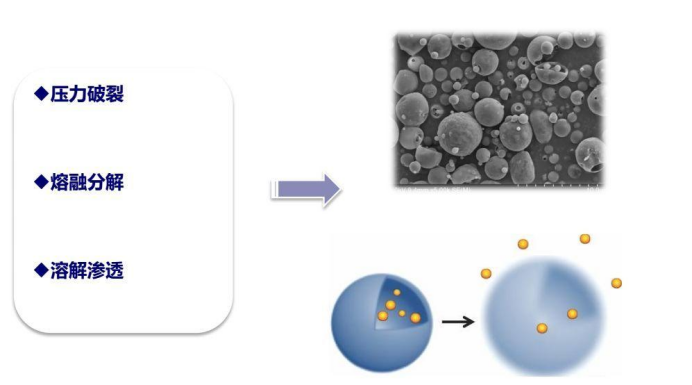

The main characteristic of microcapsule is that the material of microcapsule will not react with the encapsulated flame retardant. Once the product is exposed to high heat, the wall of microcapsule will melt and break, releasing flame retardant. Its action principle is similar to that of drug capsule.

There are two main types of capsule materials:

Natural polymer materials: animal glue, various proteins, starch, cellulose, etc; Bittern, etc;

Synthetic polymer materials: polyvinyl alcohol, PVC, polyamide, polyester, epoxy resin, etc.

At present, the most popular technology is microencapsulated red phosphorus flame retardant, which can isolate red phosphorus from the outside world by inorganic compounds and organic resin coating phosphorus, overcome the problems of red phosphorus oxidation and moisture absorption, and will not produce toxic and harmful gases in the process.

At present, it is widely used in rubber, thermoplastic resin (ABS, PA, PP, PC, pet, PBT, EVA, etc.) and thermosetting resin (epoxy resin, phenolic resin, etc.), at the same time, magnesium hydroxide or aluminum hydroxide is used as flame retardant synergism to further improve the flame retardant ability.