Four flame retardant technologies--Expansion technology

Expansive flame retardant is a kind of green flame retardant, which does not contain halogen and does not use antimony oxide as synergistic agent. The utility model relates to a compound flame retardant mainly composed of nitrogen and phosphorus, which foams and expands when heated, so it is called expansion flame retardant and is a kind of environmental protection flame retardant with low toxicity in colleges and colleges. It is recognized as one of the effective ways to realize the halogen-free flame retardant and has great potential in the flame retardant finishing of textiles.

Expansion technology and expandable flame retardant in the flame retardant system, in recent years, the development momentum is also all the way forward, with less smoke in the combustion process, no drop and no toxic and other advantages.

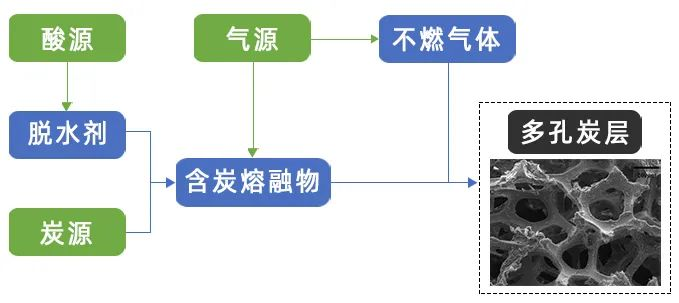

The expandable flame retardant system is generally composed of carbonizing agent, carbonizing accelerator and foaming agent. At the beginning, the inflatable flame retardant was mostly used in the coating industry, but some foreign studies also made the inflatable flame retardant system in plastics, rubber and other materials also have a wide range of applications.

Expansive flame retardants (IFR) are mainly divided into two categories: phosphorus and nitrogen flame retardants and expandable graphite. Phosphorus and nitrogen type flame retardants are divided into haplotype phosphorus and nitrogen type flame retardants and mixed phosphorus and nitrogen type flame retardants. IFR generally includes carbon sources (often polyhydroxyl compounds, such as pentaerythritol), acid sources (such as ammonium polyphosphate), and foaming agents (such as melamine).

The formation diagram of porous carbon layer is as follows:

The carbon layer thus formed makes it difficult for heat to penetrate into the condensed phase and prevents oxygen from diffusing from surrounding media into the degrading high polymer material. It also prevents the gaseous or liquid products resulting from degradation from escaping from the surface of the material.